Z-axis based on barometer

Use Cases

- Z-axis via barometer was designed for floor level detection.

- See more information within the tech blog, chapter: Barometer Calibration via an API: Reliable People Tracking in Multi-Level Facilities.

Is Z-axis altitude measurement via barometer applicable for my use-case?

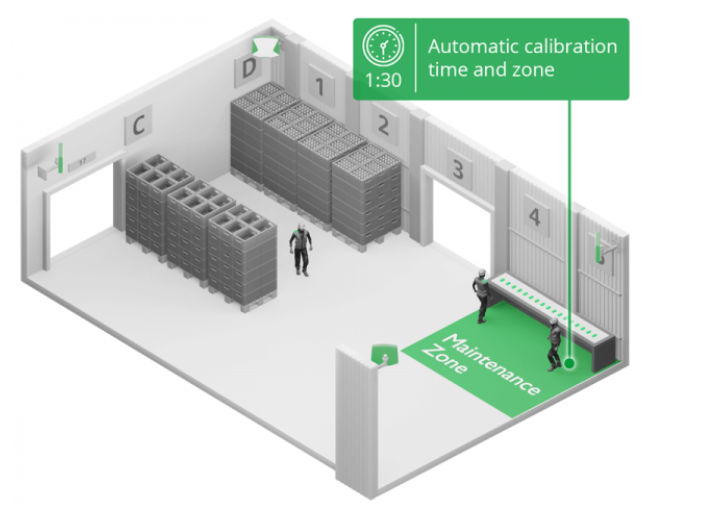

Yes, if given use case has possibility to regularly put tags to a known Z-axis to execute the recalibration.

- If you do not have tags under the control, Z-axis will NOT work as controlled recalibration cannot be performed.

Here is a list of common use-cases:

Type | Description | Barometer Suitability |

Buildings - floor detection | Automatic floor assignment. | |

Entertainment / Training / Games | Sub-meter Z-axis achievable thanks to prior calibration. | |

Warehouse - shelf detection** | Identify Z-axis of asset. | |

| Warehouse - forklifts | Forklift Z-axis of the fork. It would not work reliably with barometer |

**We do NOT recommend barometer measurement for Z-axis to identify level of shelf in warehouse.

Barometer Pros / Cons

Pros | Cons |

|

|

Required Hardware & Software

- Anchors Vista

- Tag Leonardo (with barometer)

- RTLS Studio 1.6.2 or newer

- Re-calibration feature via API is available from RTLS Studio 2.5

Principle

Simple physics - the higher you are the lower atmospheric pressure is observed.

The goal is to measure precisely Z-axis within the building. Let’s say we are interested in range 0-50 meters with sub-meter accuracy. However, atmospheric pressure sensors are designed from 0 to 9000 meters (or 1200 – 300 hPa). Therefore, we need data from sensor within very small portion of its range, moreover with very high accuracy. Therefore, data are very close to noise.

Here are some facts about pressure sensor:

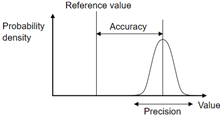

- Absolute accuracy: ± 1 hPa (or ±8 m)

- Relative accuracy: ± 0.06 hPa (or ±0.5 m)

- Pressure sensor precision: ± 0.005 hPa (or ±0.05 m)

See accuracy vs. precision, wiki page.

Since absolute pressure measurement is not accurate enough, relative measurement is employed based on pressure difference between mobile Tags and static Anchors. Both devices must be equipped with barometer and calibrated.

Calibration process

- Measure and set height for anchors manually in RTLS Studio (one-time process during deployment)

- Put Tags to a known height

- Wait until system obtains enough barometric data

Z-Axis calculation chain

Z-axis is continuously calculated in Tag refresh interval period. Firstly, data transmitted from the tag are appended with tag’s barometer, then received by set of anchors and further appended with their barometer values and forwarded to RTLS Studio where Z-axis estimation is immediately calculated and provided via API.

Challenges

- Long term barometer stability ± 1 hPa (or ±8 m) – final Z-axis from RTLS system can be precise like +-15cm after calibration. However, barometers drift away up to several meters in long-term.

Solution: Regular re-calibration of barometers. - Tag Power consumption with activated barometer – do not forget that barometer measurement consumes energy.

Solution: Please see datasheet and Tag battery life-time calculator for more info. - Tag needs to transmit during the recalibration at least 10 messages, therefore permanent sleep mode cannot be used, since tag does not send any data.

Solution: Use tags with external power supply if possible. If sleep mode needs to be used always consider barometer recalibration phase. - Barometer pressure temperature sensitivity: 0.5Pa/K, (or 1°C cca 5cm).

Solution: Not considered as an issue for Tags in indoors. - Rapid barometric change – relatively slow barometric changes like weather are compensated inherently since barometric data are collected very often from Anchors.

Solution: Rapid pressure changes like door open can be compensated thanks to density of anchors deployment which counterbalances the rapid changes also on the anchor side. - IP 67 Prevents Pressure Change on Tag

Solution: There must be hole for airflow change which should be covered with IP 67 vent stamps.